HYCRASH

HYCRASH has been developed by JSOL Corporation to allow quicker and easier inclusion of press forming into an impact analysis.

Process

Traditionally, to add the effects of press forming into an impact analysis, a full forming analysis for each of the parts would need to be carried out. This can add a significant amount of time and present a number of difficulties, such as:

- CAD data is required to mesh the die and the blank

- Detailed material data is needed to model the forming process

- Results have to be mapped from the finer mesh used in forming analysis to the coarser mesh used in crash analysis

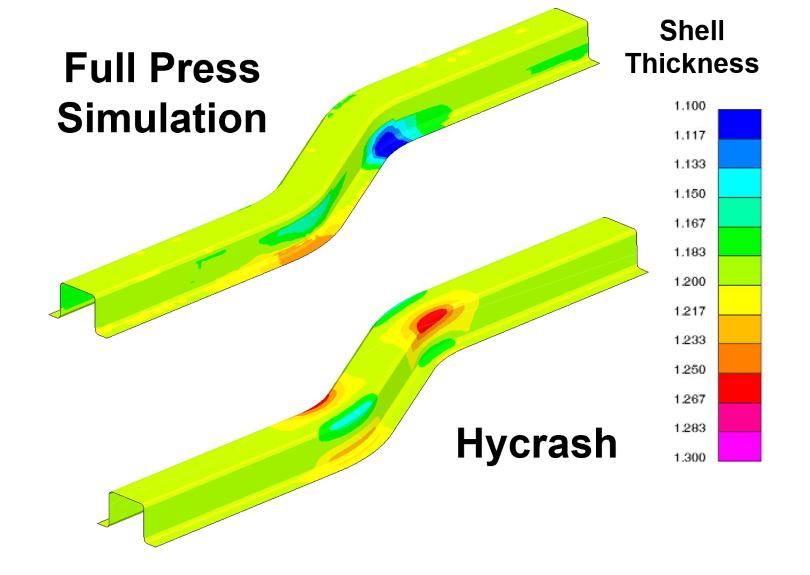

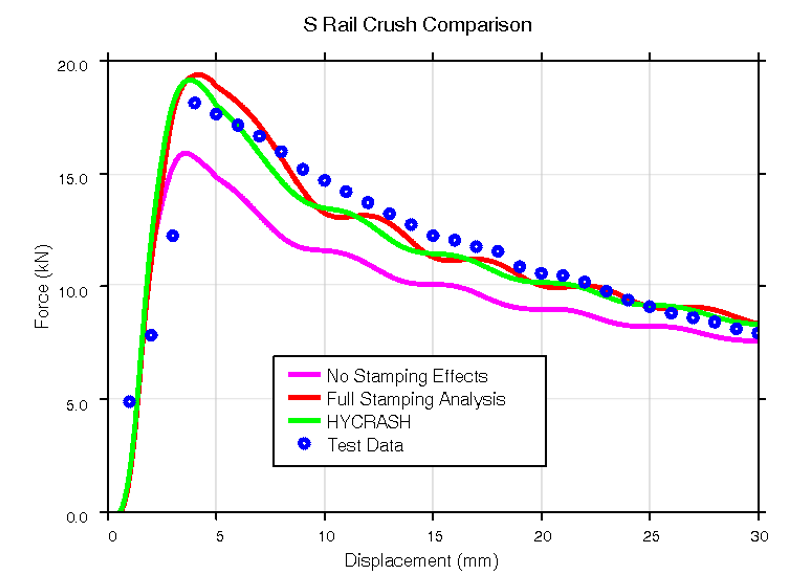

HYCRASH uses an inverse solver to calculate the plastic strain and thickness of a part based only on its final geometry. No data about the die or the blank is required. This approach provides a reasonable approximation of the forming effect in a much shorter time frame and proves more practical for use in development work.

Pre-processing

HYCRASH is integrated into Oasys PRIMER using JavaScript. The user only needs to open the model in PRIMER, run the JavaScript and select the relevant parts. The script will then run HYCRASH for each of the parts selected and merge the results back into the main model.

LS-DYNA input data produced

Shell thickness (*ELEMENT_SHELL_THICKNESS)

Plastic strain (*INITIAL_STRESS_SHELL)

Discover the rest of our products

We distribute a range of other software products as well as various dummy models produced by FAT and LSTC which complement our core software suite. We are also proud to develop a selection of barrier and pedestrian impactor models in collaboration with Cellbond.